Our Services – Biogas and BIO CBG Plant Manufacturing Solutions in India

KPO Group is a leading Biogas Plant Manufacturer in India and a trusted BIO CBG EPC Company, delivering end-to-end solutions for BIO-CBG and industrial biogas projects. From concept to commissioning, we support clients with technology, approvals, documentation, and long-term operational guidance under the SATAT initiative.

We serve investors, industries, and entrepreneurs searching for Biogas Plant near me, BIO CBG Plant near me, and SATAT Bio CBG Plants near me, with PAN-India execution and localized project support. We also provide complete DPR preparation for BIO CBG plant India , PESO license for CBG plant India, MNRE approvals, and MNRE subsidy for BIO CBG plant India as part of our integrated CBG EPC services.

Get Free Consultation Download Brochure

Site Planning and Feasibility Studies are critical for the success of any BIO-CBG project. As experienced Biogas Plant Manufacturer in India , we conduct detailed assessments of land suitability, feedstock availability, and energy demand to ensure technical and financial viability.

Our feasibility services support CBG Plant under SATAT by enabling informed decisions through DPR preparation for BIO CBG plant India , capacity planning, and cost evaluation. This structured approach reduces project risk and forms a strong base for BIO CBG plant turnkey solutions in India.

As experienced CBG EPC Company, we integrate engineering best practices with regulatory compliance. We also provide DPR preparation for BIO CBG plant India and technical documentation to support CBG Plant under SATAT projects across India.

Plant Installation and Commissioning is a critical phase in delivering a successful BIO CBG plant turnkey solution in India. From groundwork to full operational readiness, our team ensures every aspect of industrial biogas plant installation India is completed on time and in compliance with regulatory standards.

As a trusted CBG EPC Company, we manage equipment erection, process integration, and trial runs. We also support DPR preparation for BIO CBG plant India and on-site documentation for CBG Plant under SATAT projects across India, ensuring smooth commissioning and operational efficiency.

Licensing and Compliance Support helps ensure your BIO-CBG project meets all statutory and regulatory requirements. We assist with government approvals, environmental clearances, and mandatory licenses for CBG Plant under SATAT.

Our team provides expert support for PESO license for CBG plant India and MNRE approvals for BIO CBG plant India, simplifying regulatory processes through reliable CBG plant legal and regulatory support India .

Bank Finance Facilitation supports investors in securing funding for BIO-CBG and biogas projects through structured financial guidance. Our experts assist in creating bankable project documentation aligned with lender and institutional requirements.

We coordinate with banks and financial institutions to streamline loan evaluation, cost assessment, and approval processes for BIO CBG plant cost India . This ensures faster financial closure for projects implemented under CBG Plant under SATAT initiatives.

Feedstock Cultivation Guidance focuses on ensuring a consistent and reliable raw material supply for BIO-CBG plants. KPO Group offers technical advisory for cultivating high-yield energy crops suited for BIO CBG plant operations in India.

We specialize in advisory support for Napier grass based bio CBG Plant in India , covering best practices for plantation planning, harvesting cycles, and long-term feedstock sustainability.

Ongoing Maintenance and Technical Support is designed to maximize plant uptime and long-term reliability. Our team provides structured maintenance planning, operational monitoring, and technical assistance to sustain industrial biogas plant performance in India.

We support continuous process efficiency, safety checks, and system optimization for BIO CBG plant turnkey solutions India , helping operators maintain consistent gas output and stable plant operations over time.

The Continuous Stirred Tank Reactor (CSTR) is a proven anaerobic digestion system widely used in industrial biogas plant installation India. Designed to handle semi-solid biomass and mixed organic waste, the CSTR ensures uniform mixing, controlled temperature, and stable microbial activity for consistent biogas generation and nutrient-rich digestate.

As an experienced Anaerobic CSTR digester manufacturer India , KPO Group engineers robust digester systems suitable for long-term operation in BIO-CBG and waste-to-energy projects.

Technical Specifications:

- Process Type: Mesophilic Anaerobic Digestion

- Operating Temperature: 32°C – 38°C

- Organic Loading Rate: 10–12%

- Discharge: Liquid Slurry

- By-product: Solid Organic Manure (20–25%)

Feedstock:

- Pressmud

- Cow Dung

- Poultry Waste

- Food Waste

- Vegetable Waste

H₂S Removal System plays a vital role in improving biogas quality by removing corrosive sulfur compounds before gas utilization. Effective hydrogen sulfide removal enhances plant safety, protects critical equipment, and supports long-term operational reliability.

KPO Group provides advanced solutions for Biogas purification H₂S removal India , helping BIO-CBG plants achieve cleaner gas suitable for engines, compression, and upgradation systems used in industrial biogas and BIO-CBG projects.

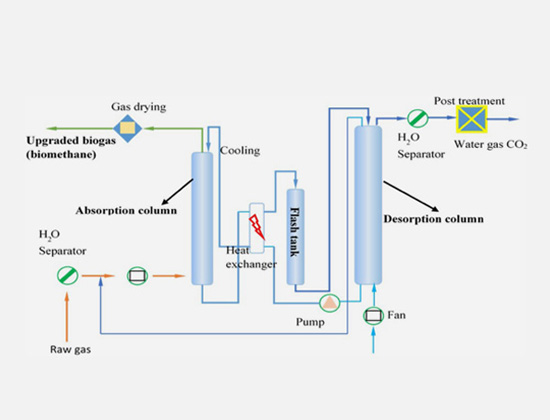

Water Scrubber technology is widely used in biogas upgradation to enhance methane concentration by separating unwanted gas components through controlled absorption. The system operates using water as a natural scrubbing medium, making it a reliable and environmentally friendly solution.

KPO Group integrates water scrubber systems as part of advanced BIO-CBG gas upgradation solutions , helping plants achieve consistent gas quality suitable for compression, bottling, and commercial utilization in BIO-CBG and industrial biogas projects.

PSA Purification Plant is an advanced biogas upgradation solution designed to deliver high-purity BIO-CBG by selectively separating unwanted gas components under controlled pressure cycles. This technology enables stable methane enrichment while maintaining consistent output quality.

KPO Group implements PSA-based systems as part of PSA technology for BIO CBG plant India , supporting large-scale CBG Plant under SATAT and commercial BIO-CBG applications requiring pipeline-grade gas standards.

Membrane Biogas Separation utilizes selective permeation to upgrade raw biogas into high-quality biomethane suitable for compression and commercial use. The system operates through multi-stage membrane modules that allow controlled gas separation with minimal energy loss.

KPO Group deploys membrane-based solutions as part of advanced biogas upgradation solutions for BIO CBG plants in India , helping projects achieve consistent methane purity required for CBG Plant under SATAT and industrial applications.

MSW-based Bio CBG Plant transforms municipal solid waste into clean, vehicle-grade Compressed Biogas and high-quality organic fertilizers. By combining waste segregation, anaerobic digestion, and gas purification, KPO Group provides sustainable solutions for urban waste management and renewable energy production.

Our plants contribute to reducing landfill volumes and methane emissions while generating eco-friendly fuel for transportation. Through this integrated approach, we support the circular economy and create employment opportunities, making waste-to-energy projects commercially viable. BIO CBG plant turnkey solutions India ensure end-to-end project execution from planning to commissioning.

Benefits:

- Reduces landfill and methane emissions.

- Produces clean, renewable CBG fuel.

- Generates organic fertilizers for agriculture.

- Promotes circular economy and job creation.

We turn waste problems into green energy opportunities.

Looking to set up a Biogas or BIO‑CBG Plant?

Partner with KPO Group for reliable, compliant, and profitable Biogas or BIO‑CBG solutions. Contact us today to discuss your project requirements.

Get Project Consultation Explore Our Technology